IMMERSION COOLING: THE SAFEST BATTERY TECHNOLOGY ON THE MARKET?

April 23, 2020

XING MOBILITY - INDUSTRY INSIGHTS

Thermal management in battery systems represents one of the most crucial challenges facing the electric vehicle (EV) industry to date, and this is largely due to its impact on a number of key battery features including charging speed, energy density and safety. It is unsurprising therefore that leading experts and market research organisations are dedicating substantial research resources to the subject of “cooling”.

As part of their Thermal Management for Electric Vehicles 2020-2030 report, IDTechEx recently released an article entitled: Immersion of Electric Vehicle Batteries: The Best Way to Keep Cool? which specifically explores the method of Immersion Cooling in EVs and XING Mobility’s role in developing this technology. In addition to sharing some of IDTechEx’s insightful review of this cooling technology, we wanted to weigh in with some further observations surrounding the potential for Immersion Cooling to bring enormous safety gains to EV markets.

"Charging a battery quickly generates a lot of heat, with the extra energy capacity of modern and upcoming electric vehicle batteries, extracting this heat becomes more challenging. If this heat is not distributed effectively, not only is the performance and lifetime of the battery greatly reduced, but thermal runaway and vehicle fires are a potential hazard. Immersion cooling is an emerging potential alternative to traditional battery cooling methods."

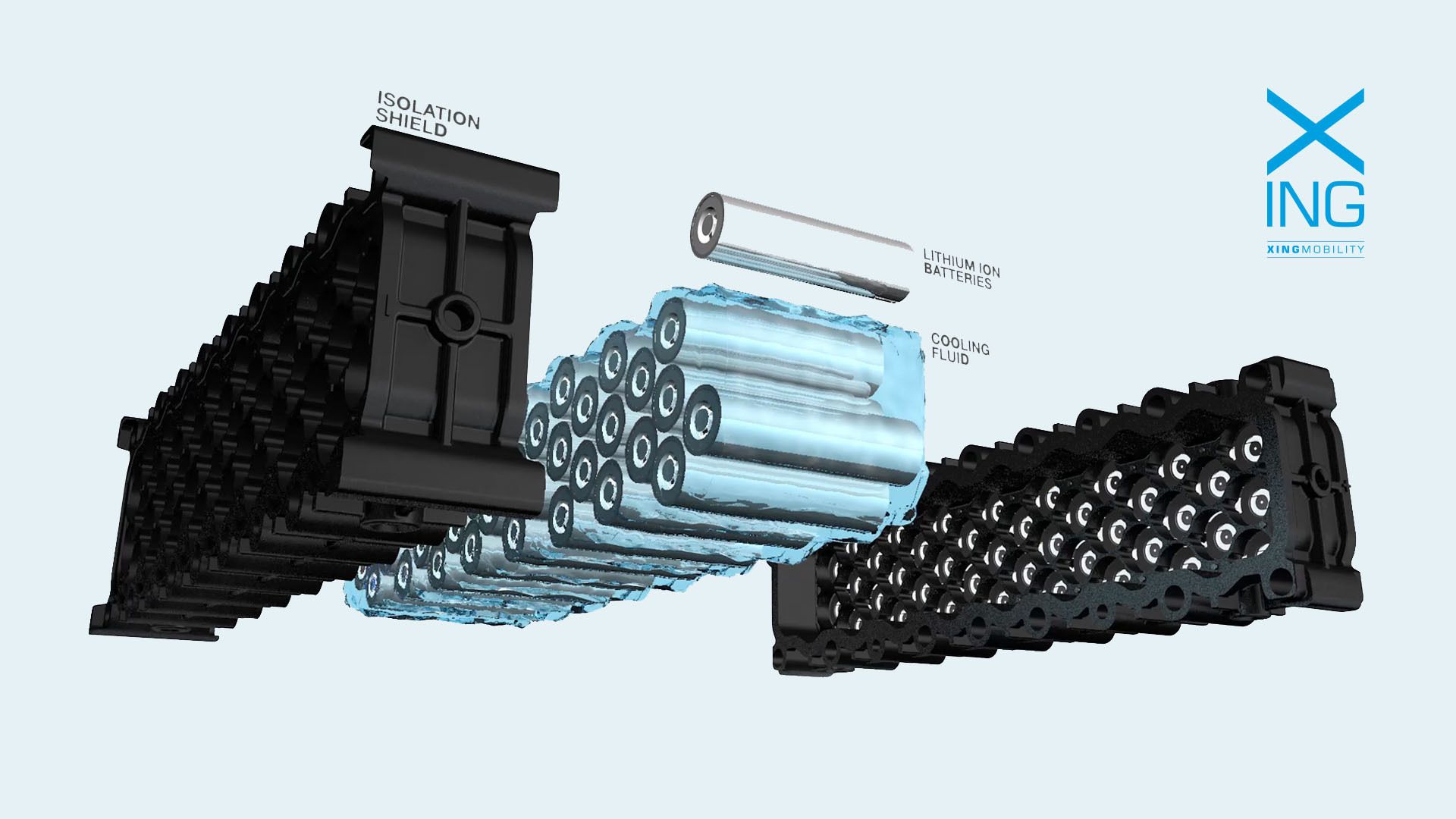

The first commercially available example of immersion cooling in electric vehicles was introduced by XING Mobility in 2018 in the form of the IMMERSIO™ Battery Pack System. The technology involves submerging lithium-ion battery cells directly in a non-conductive liquid coolant, and in doing so achieving effective distribution of heat and homogeneity between the battery cell temperatures. XING’s IMMERSIO™ uses 3M Novec Engineered Fluid, a non-flammable, non-conductive engineered fluid. Notably, the flame-retardant nature of this fluid acts as a safety feature, suppressing overheating or fire events before they propagate between cells, and reducing the risk of thermal runaway (the spread of fire from cell to cell).

This innovative technology drastically contrasts from air cooling, liquid pipe cooling or other thermal management methods that rely on thick enclosures or the indirect release of fire suppression fluids for safety, which tend to only serve to slow down risks to the battery pack and vehicle user. To illustrate the dramatic improvement in safety, XING Mobility have recently released a video of IMMERSIO™ undergoing a nail penetration test, in which a nail is slowly inserted into a battery cell within a pack to deliberately activate a fault and initiate thermal runaway.

In the Immersion-Cooled pack, the fluid immediately acts to prevent overheating in the cell, and the only visible result is a small amount of air pressure being released from the pack. In contrast, the unprotected control example on the left sees the pack go into thermal runaway almost immediately.

Due to more demanding nature of vehicle usage in industrial vehicles in comparison to passenger cars, and an increased concern regarding user safety and liability, heat control is of particular critical in specialty markets:

"While most major OEMs in the passenger car market are utilizing air or water-glycol cooling methods, some suppliers are turning to new methods to meet the increasing thermal demand on vehicle batteries. This is especially true when considering more specialized markets such as electric construction and mining vehicles, in this scenario extremely intense battery discharge is required and hence a serious amount of heat is generated. XING Mobility are a company specializing in the more niche electric vehicle markets with their modular immersion-cooled battery packs utilizing 3M's Novec fluid."

As a result of the greater demands for achieving significantly higher discharge rates, XING Mobility is particularly invested in serving the Construction, Agriculture and Mining industries which have a substantial need for energy-dense, intelligent battery solutions with advanced safety features. In addition to being able to remain competitive by offering these industries the performance and safety they require, the method of Immersion Cooling unlocks the ability to safely serve a wide range of operating environments, including extremely high or low temperatures, high altitudes, and challenging locations such as mining site and underwater marine applications.

Originally having developed this pioneering battery technology for a in-house developed 1 Megawatt supercar - Miss R, XING Mobility is a total solution provider delivering complete drivetrain solutions designed to work seamlessly with IMMERSIO™. In 2019, XING Mobility was described as the leading company in Immersion, or “forced convection”, cooling in EVs by Ricardo - one of the worlds largest automotive consulting firms - during a presentation delivered at the Battery Show, Europe in Stuttgart.